12V Broadcast Illuminated Push Button Switch

The Video LED illuminated push button with a 15mm clear cap is an innovative and practical component designed to enhance user interfaces across a range of applications.

The Video LED Illuminated Push Button with a 15mm clear cap is a sophisticated and versatile component designed for modern electronic applications where both visual feedback and user interaction are essential. This push button switch combines robust construction, bright LED illumination, and a sleek clear cap, making it an ideal choice for a variety of devices and control panels.

Technical Specifications

Diameter: 15mm

Cap Type: Clear, allowing full visibility of the LED illumination

LED Colors: Red, green, blue, RGB, or customizable options

Operating Voltage: Typically 12V DC for LED illumination

Current Rating: 50mA

Switch Type: Momentary or latching, based on the model

Contact Configuration: SPST (Single Pole Single Throw) or SPDT (Single Pole Double Throw)

Mounting Type: Panel mount or PCB mount

Material: Plastic or metal bezel options

IP Rating: Up to IP65 for dust and water resistance (optional)

Operating Temperature: -20°C to +70°C

Mechanical Life: Up to 500,000 cycles

The Video LED Illuminated Push Button with a 15mm clear cap is a high-quality, reliable, and visually appealing component designed to enhance user interfaces across various electronic applications. Its combination of bright LED illumination, durable construction, and flexible mounting options make it an excellent choice for designers and engineers looking to improve both the functionality and aesthetics of their products. Whether used in gaming machines, control panels, or automotive systems, this push button switch delivers outstanding performance and user satisfaction.

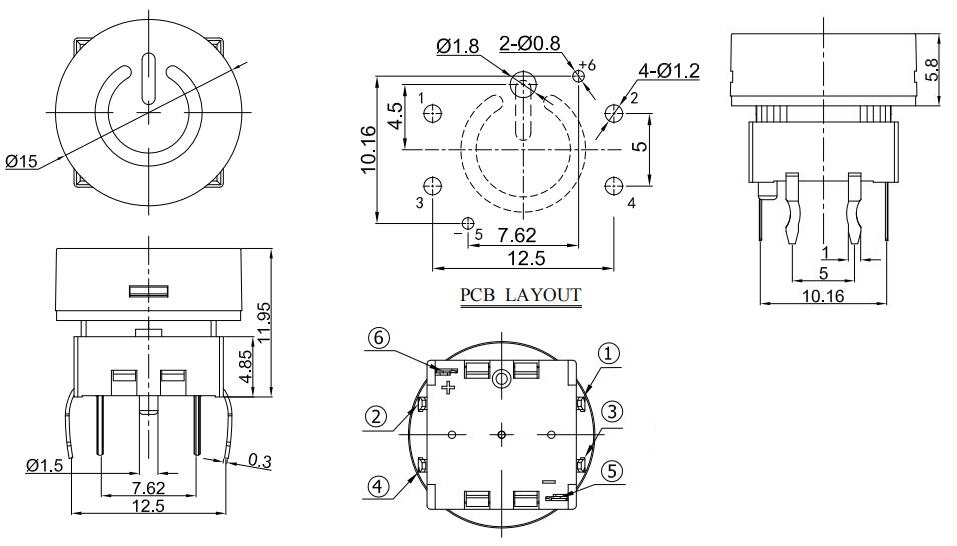

PRODUCT DIMENSION

PRODUCT CATEGORY

Illuminated Tactile switches, button switches, toggle switches, rocker switches, slide switches, microswitches, sockets and connectors, as well as hardware stamping and plastic injection.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Bella

Phone: 15999819066

E-mail: rucoe@rucoe.com

Whatsapp:+86-15999819066

Add: Taoyuan Street, Nanshan, Shenzhen